Overhaul of transmission gears

Transmission gears often work at changing speeds and under load, and the gear tooth surfaces are impacted by impact loads,

resulting in damage to the gears (especially the tooth surfaces). Common damages include:

Gear wear Under normal working conditions, the tooth surface of the transmission gear shows uniform wear, and the wear along the tooth length should not exceed 30% of the original tooth length; the tooth thickness should not exceed 0.40.

It can be measured by a dial indicator or soft metal rolling method. If the clearance is exceeded, it should be replaced in pairs.

The meshing clearance of the running gear should generally be 0.15-0.26mm, and the use limit should be 0.80mm; the meshing clearance of the engaging equipment should be 0.10-0.15mm, and the use limit should be 0.60mm.

Gear teeth are broken The broken gear teeth are mainly caused by the unsatisfactory gear meshing clearance, improper meshing position of the gear teeth, or a significant impact load during work.

If the edge of the gear teeth is not more than 2mm small broken, it can be used after grinding with oil stone; if it exceeds this range or there are more than three small broken, it should be replaced in pairs.

The end face of the constant meshing gear is worn There should be an axial clearance of .10-0.30mm on the end face of the helical teeth in regular meshing to ensure the flawless operation of the gear.

If the tooth end is worn and grooved, it can be ground and repaired, but the grinding amount should not exceed .50mm.

Constant meshing gear journal, needle bearing, and seat hole wear The clearance between the meshing gear seat hole, the needle roller bearing, and the journal should be 0.01-0.08mm; otherwise, it should be replaced.

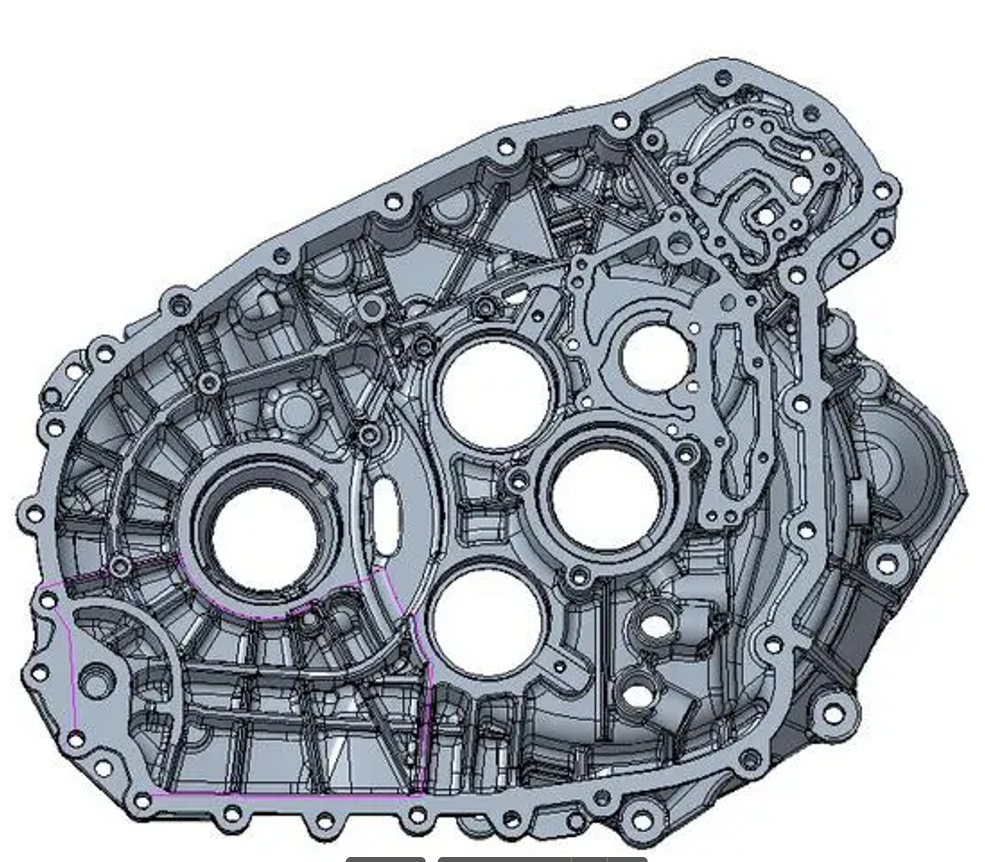

Overhaul of the Transmission Housing

The transmission case is the essential part of the transmission assembly, which is used to ensure the correct position of each piece in the transmission and bear a specific load during work. Common damages include:

Wear of bearing seat hole The wear of the bearing seat hole of the housing will destroy its assembly relationship with the bearing, directly affecting the transmission input and the relative position of the output shaft.

The matching clearance between the path and the seat hole should be 0-0.03mm, and the maximum service limit is 0.10mm.

Otherwise, they should be replaced with the shell or socket for repair.

Repair threaded shell holes The thread damage to the oil injection rosette hole, the oil drain plug hole, and the deterioration of the threaded hole of the connecting bolt between the shells can be repaired by inserting the plug.

Overhaul of the transmission shaft

During the working process of the transmission, each bearing is subjected to changing torsional moment and bending moment. The common damages of each shaft are:

journal wear Excessive wear of the journal will offset the axis of the gear and change the gear’s meshing clearance, resulting in noise during transmission.

At the same time, the matching relationship between the journal and the bearing will be damaged, and the operation may cause ablation.

Therefore, it is required that the journal wear at the interference fit of the roller bearing is not more than 0.02mm, and the journal wear of the needle roller bearing is not more than 0.07mm.

Otherwise, it will be replaced or repaired by chrome plating.

Wear healthy teeth The wear of the healthy teeth is more severe on the stressed side.

It can be checked with the spline sleeve. When the wear of the healthy teeth exceeds 0.25 or the match with the original keyway exceeds 0.40mm, the engagement ring gear of the gear, the combination sleeve, and the healthy tooth circumference cooperate with the trainee.

When the length is more significant than 0.30mm, when the probation of the semicircular key and the journal keyway exceeds 0.08mm, the shaft with the tooth circumference of the keyway should be repaired or replaced.

Bending inspection of the transmission shaft Use a thimble against the thimble holes at both ends of the transmission shaft, and use a dial indicator to check the radial runout of the post.

The deviation should be less than 0.10mm.

If it exceeds, the pressure should be corrected and repaired.

Synchronizer Repair

Overhaul of the lock ring inertial synchronizer: the cone angle a of the lock ring is about 6 degrees to 7 degrees.

During use, the cone angle increases due to deformation and cannot be synchronized quickly, so it should be replaced in time.

Lock pin type inertial synchronizer: The significant damage to the lock pin type synchronizer is the cone ring and the cone disc wear.

When the 0.40mm deep thread groove on the cone ring slope is worn to 0.10mm deep, it should be replaced. If the end face of the cone ring has If there are scratches, end face turning is required, but the cumulative turning two should not exceed 1mm; otherwise, it should be replaced.

Conclusion

If you want to learn about overhauling an electric tricycle transmission, this guide is for you. For more guides, please subscribe.